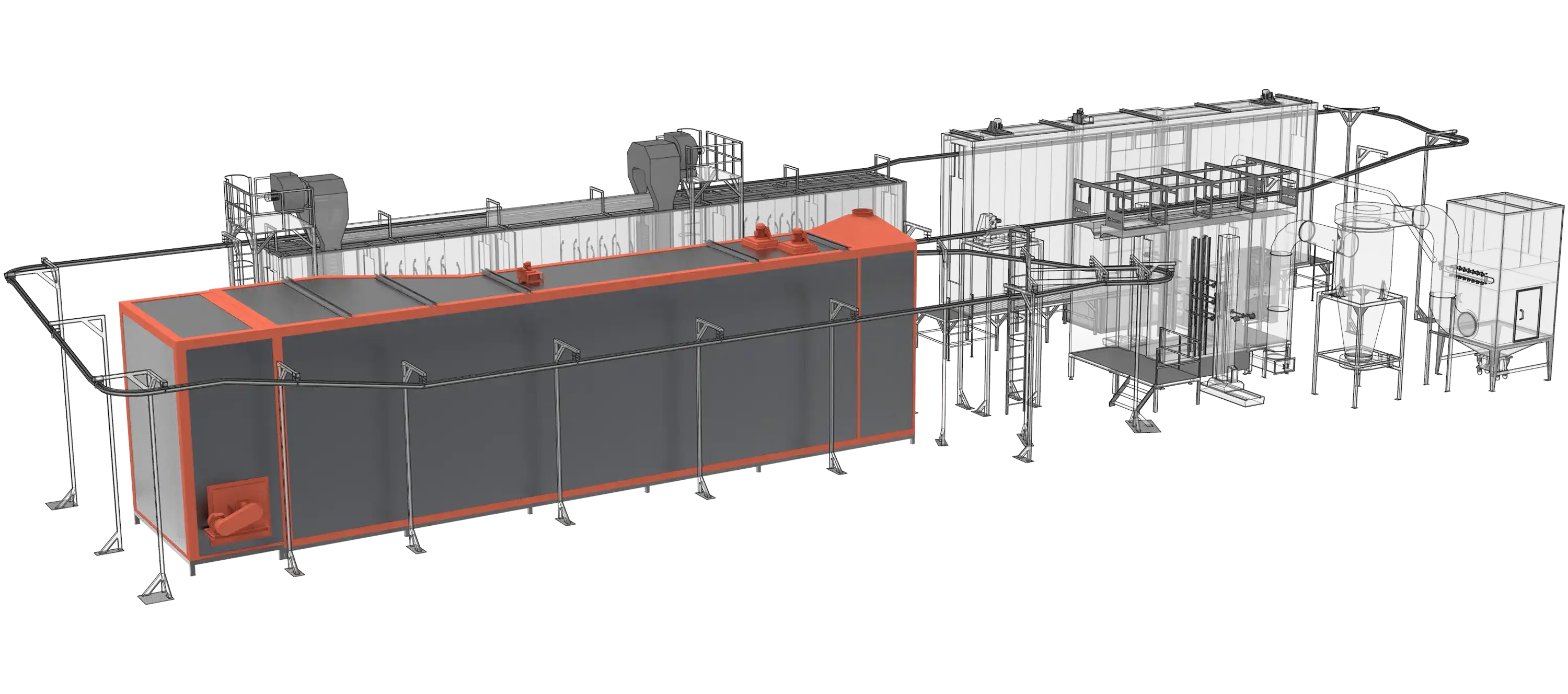

Band Ovens:

It is ideal for continuous operations and is often used in mass production lines.

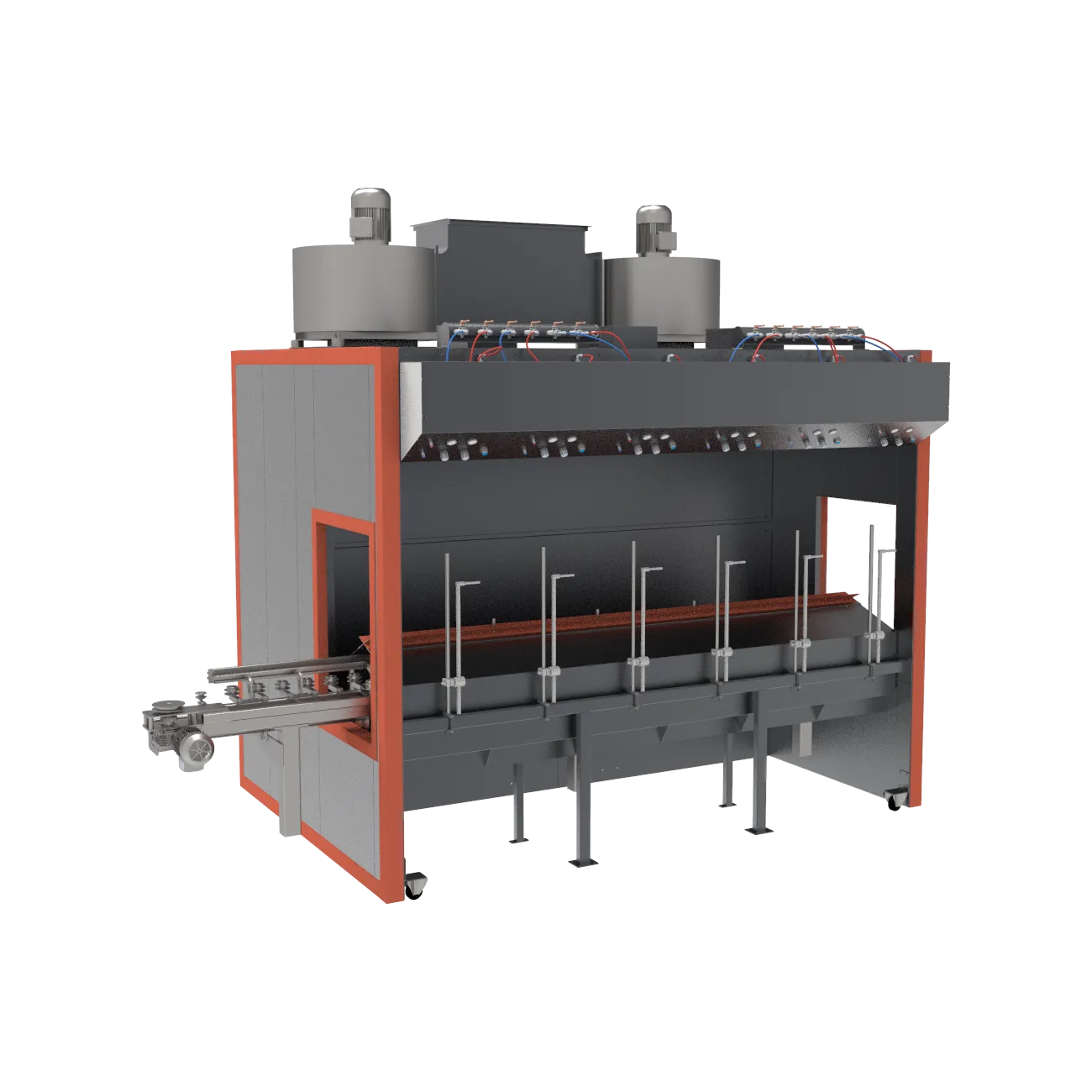

IR Ovens:

It provides fast and effective drying using short wave infrared heaters.

Dipping Type Oven:

It is especially preferred in heat treatment processes of metal parts.

Step Oven:

It allows temperature adjustment at different stages and is suitable for special processes.

High Temperature Non-Stick Baking Ovens:

It is designed specifically for non-stick coatings and can operate at temperatures between 300°C and 600°C.

Box Type Ovens:

Available in adjustable sizes suitable for parts of different sizes.

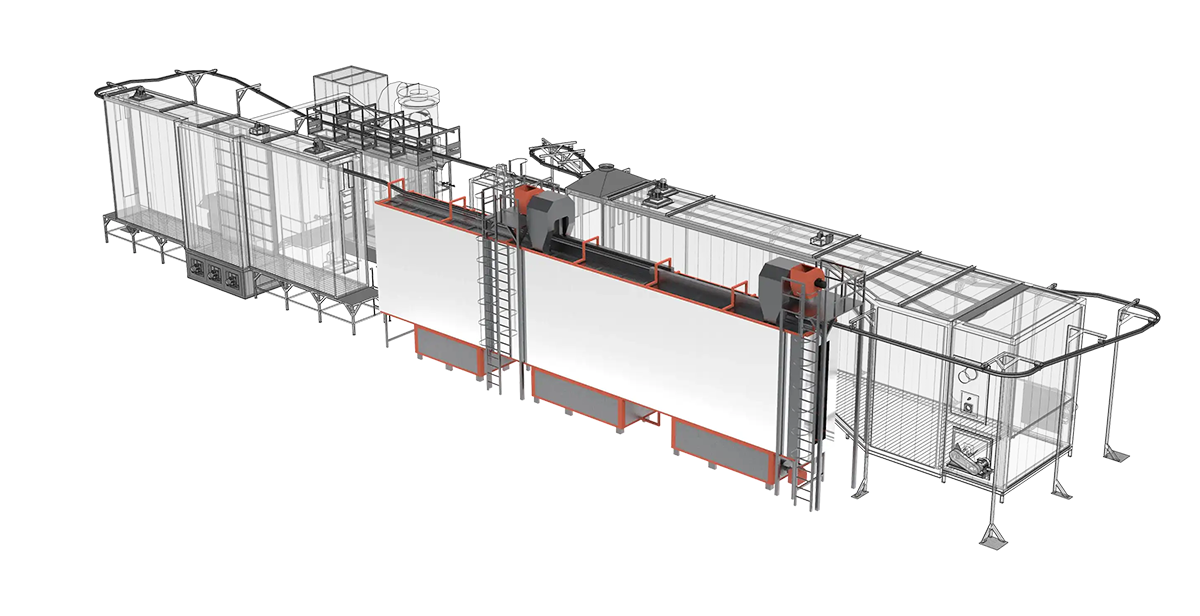

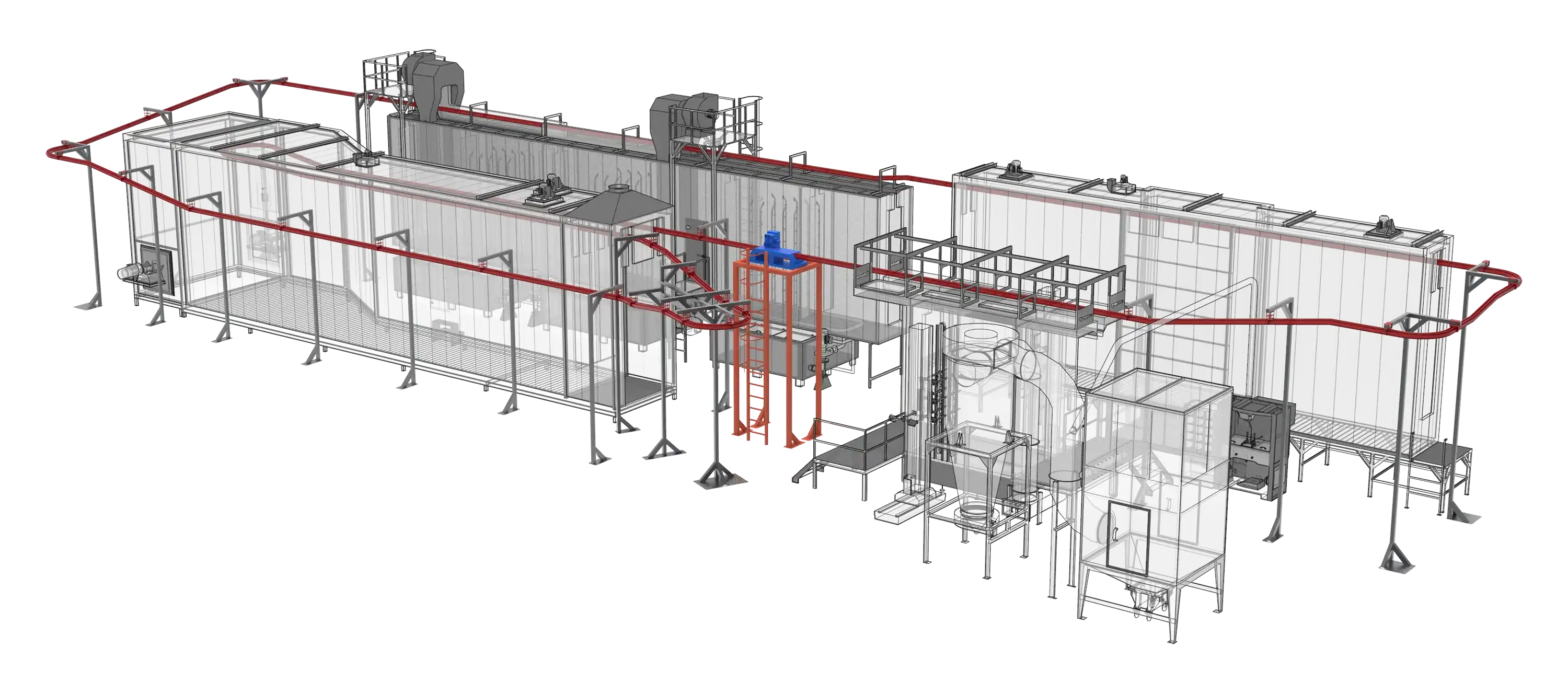

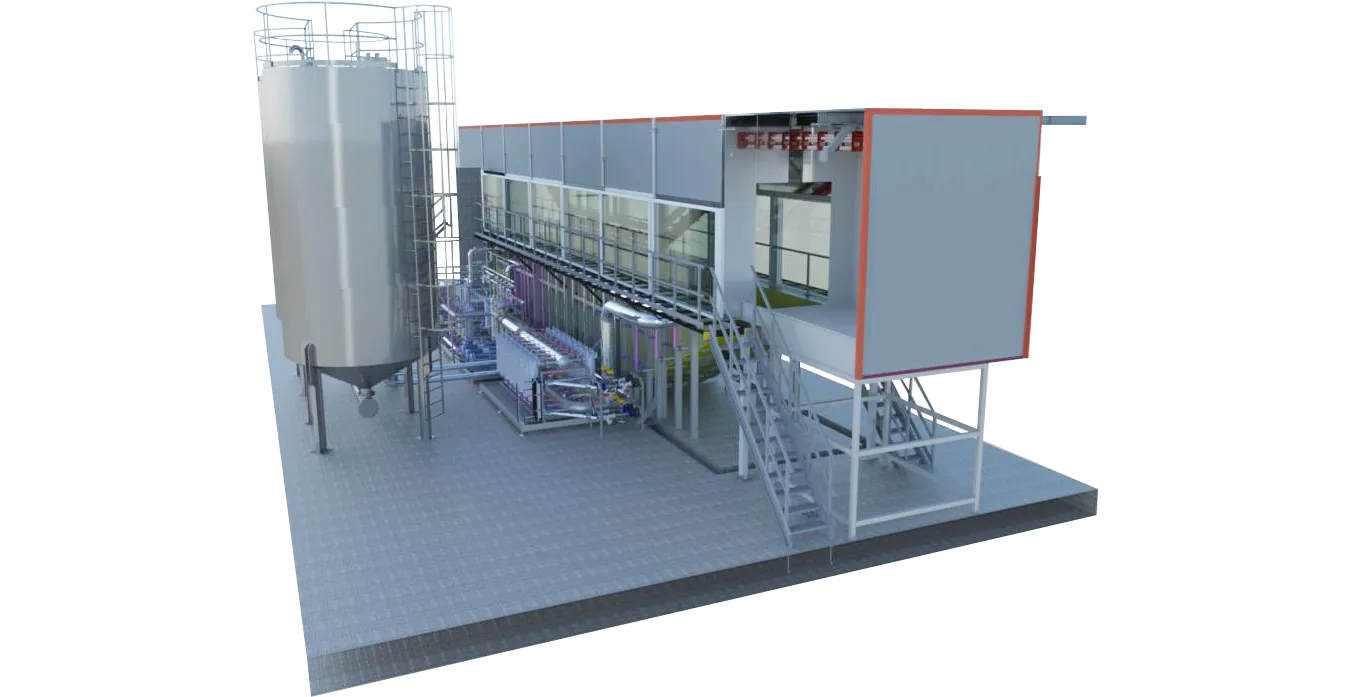

Tunnel Type & U-Turn Continuous Ovens:

Space-saving designs for long, narrow passages.